Measurement of the amount of laser light is achieved through what is commonly known as a power meter. A Power Meter is a sensor that collects laser light, converts that laser light to an electrical signal which is then extrapolated into the amount of Power or Energy that the light is producing, ultimately providing a reading to an attached meter or local PC for analysis. This process usually only takes a few seconds, but can vary depending on the technologies used. These measurements are important to collect and analyze, especially during the production phase of the laser's life, because it tells the laser user how laser performance is changing and how these changes affect the laser's application to the process.

Overall Beam Diameter must also be measured. There are different methods and schools of thought that can be used: D4σ, 13.5% of Peak, and 10/90 Knife-Edge all calculate beam diameter but can produce very different results. All are used by people in different industries, with different backgrounds and experiences.

The roundness of the beam, or Ellipticity value, must be considered when calculating beam diameter. Beam shape, and how the energy is distributed across the beam profile, must be understood. Is the beam a Gaussian beam? Is it a flat top beam? All these measurements, and more, can and should be measured by an industry-standard beam profiling system when attempting to understand how the laser is applied to the process.

Beam Quality is another consideration that must be taken into account, whether you're selecting a laser, developing the application with a laser, or integrating or commissioning a laser source into a system. In most cases, beam quality analysis is rarely considered once the laser is deployed into production, so it is important to consider this analysis before this last phase of the laser's life cycle.

Beam Quality can be expressed as an M2 value, with the value of 1.0 being a perfect laser. Beam Parameter Product (BPP), and K are also expressions of laser quality. Laser sources have improved with respect to beam quality and the efficiency with which the laser light is produced, and different laser sources have their own strengths when it comes to the different processes where a laser is used.

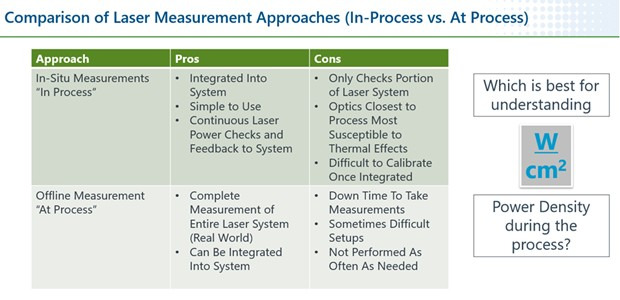

It is important for the laser user to understand how the laser interacts with the process. Measuring the amount of laser light, the Beam Size at the process, and how and why these two important measurements change over time, is vital to fully understanding system performance and ensuring more consistent long-term performance.

Ultra-High Velocity

Ultra-High Velocity